Reliable Testing for Leak-Proof Performance

Hydrostatic Pressure Testing is one of the most trusted methods to verify the strength, durability, and safety of pipelines, tanks, boilers, and pressure vessels. At [Your Company Name], we provide end-to-end hydrostatic testing solutions that ensure your equipment meets both industry standards and safety regulations.

Why Hydrostatic Testing?

Over time, equipment exposed to high pressure, chemicals, and temperature variations may weaken or develop hidden leaks. Hydrostatic testing helps in:

✅ Detecting leaks and weaknesses in pipelines or tanks

✅ Verifying pressure resistance and operational safety

✅ Ensuring compliance with international safety codes

✅ Preventing costly breakdowns or hazardous failures

Our Testing Process

- Preparation & Inspection – Thorough cleaning and sealing of equipment.

- Filling with Water – The system is safely filled with water to eliminate air pockets.

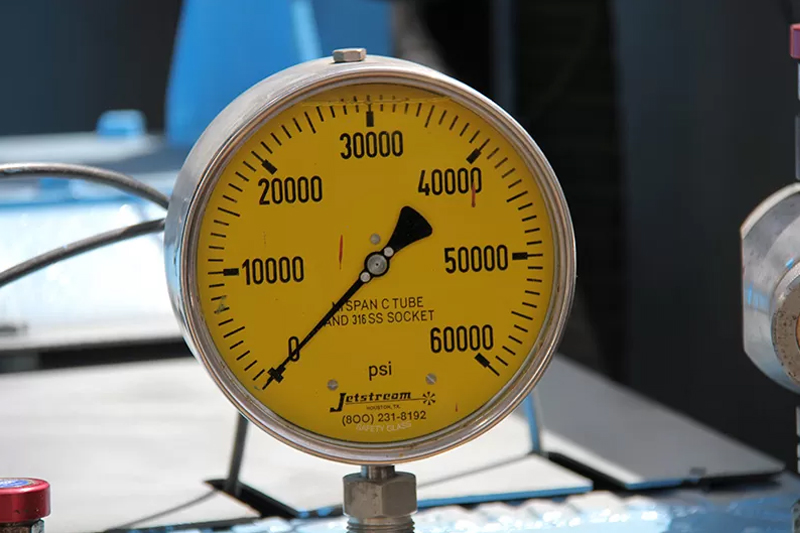

- Pressurization – Pressure is gradually applied using calibrated pumps.

- Monitoring – Equipment is observed for leaks, deformations, or pressure drops.

- Certification – A detailed test report and compliance certificate are provided.

Where We Provide Testing

- Pipelines (oil, gas, and water)

- Boilers and pressure vessels

- Storage tanks

- Heat exchangers & condensers

- Industrial equipment requiring pressure validation

Why Choose Us?

- 🔧 Advanced Testing Equipment – Ensures accuracy and reliability

- 👷 Expert Team – Experienced engineers and technicians

- 📋 Certified Procedures – Compliant with ISO, ASME, and other standards

- ⏱️ Minimal Downtime – Fast and efficient execution

- 🛡️ Safety First – Tested under strict safety protocols

Get Your Equipment Certified Safe

If you need leak-proof assurance for your critical equipment, our hydrostatic testing service is the most effective solution.

📞 Contact us today to schedule a test or request a free consultation.